If you’ve worked with different industrial materials, you know how some of them look pretty ordinary on the surface but end up doing the heavy lifting. Monofilament yarn is exactly that kind of material. It doesn’t stand out at first, but once you use it, you understand why so many manufacturers rely on it.

At Shanthi Industries, we keep hearing the same thing from clients in the U.S., Germany, Italy, Turkey, Vietnam, Thailand, South Korea, and Brazil they want innovation in every supply. Something that behaves the same way every time. And monofilament yarn usually does that without causing complications. Here’s why it’s so widely used.

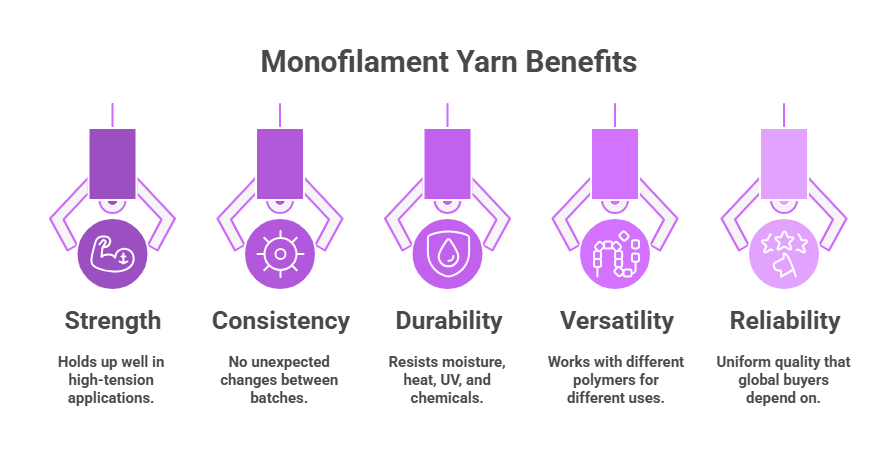

1. It Handles a Lot More Stress Than It Seems Capable Of

Monofilament yarn doesn’t look particularly strong, but it’s surprisingly tough. Because it’s made from a single solid strand, the strength doesn’t fluctuate. There’s no weak twist, no uneven tension.

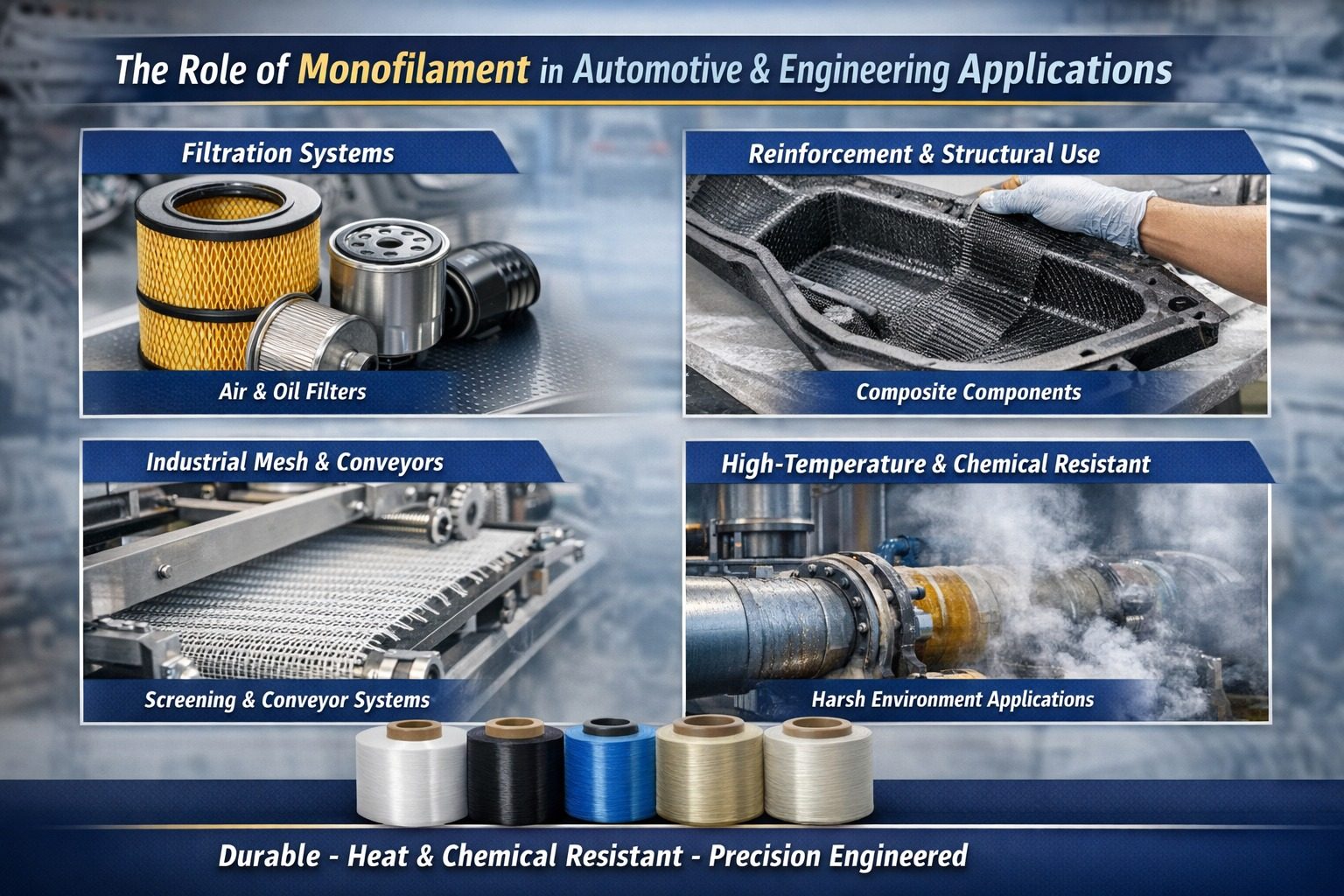

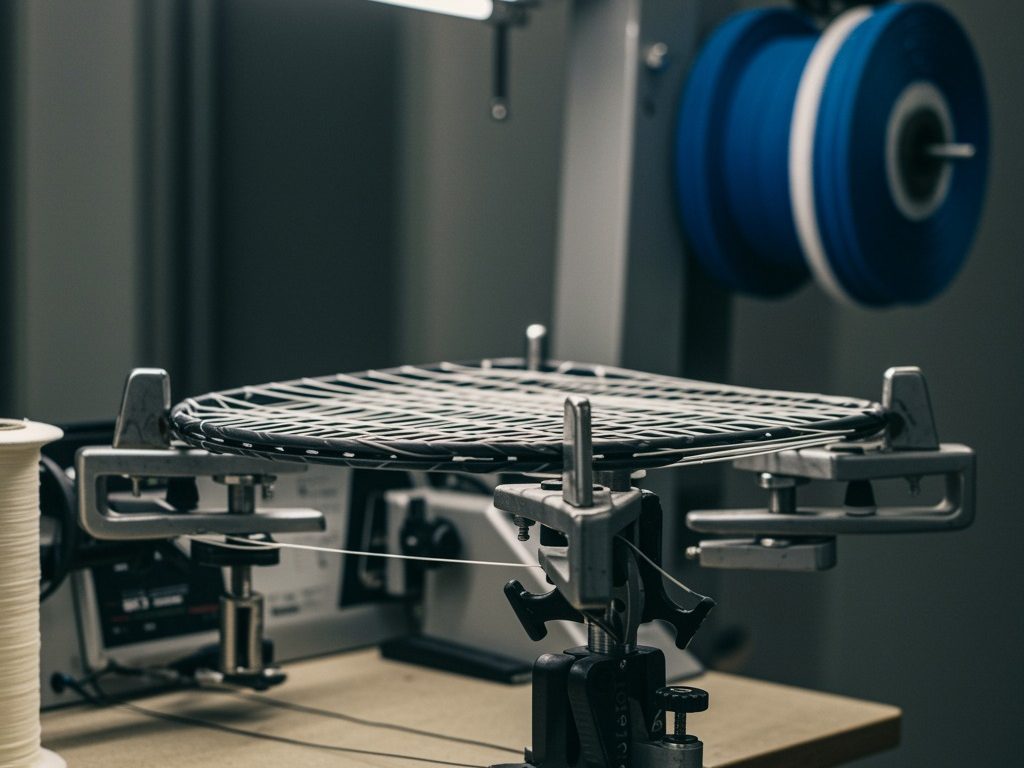

That’s why you see it in fishing nets, industrial brushes, zipper parts, filtration fabrics — places where you can’t afford sudden breaks. It’s dependable in a way people often don’t expect.

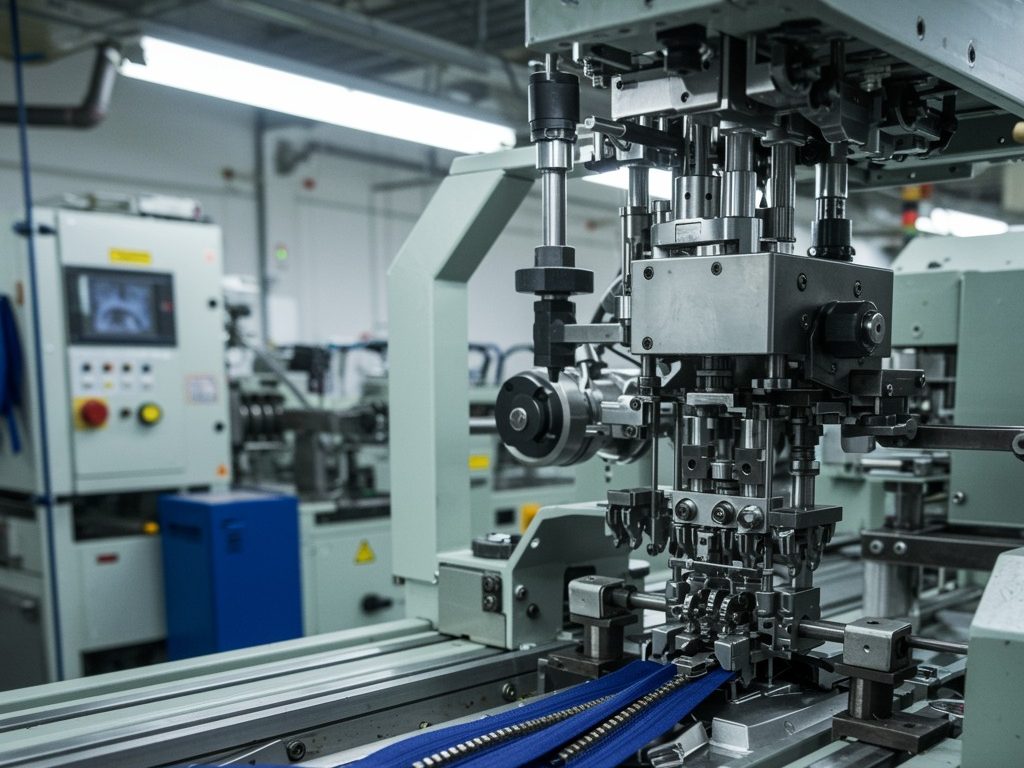

2. You Don’t Get Random Surprises in Production

One of the biggest frustrations in manufacturing is inconsistency. If your material changes from batch to batch, everything else starts to go wrong.

Monofilament yarn stays steady.

The diameter, the stiffness, the texture — everything holds its place.

For an exporter like Shanthi Industries, this matters a lot because overseas customers expect the same quality every time they reorder. And monofilament helps meet that expectation naturally.

3. It Doesn’t React Badly to Different Conditions

Some materials just don’t cooperate when exposed to moisture or heat or sunlight. Monofilament yarn handles these a lot better — depending on the polymer, it resists water, heat, chemicals, UV exposure, even fungus in some cases.

So, whether it ends up outdoors, near water, in filtration, or in automotive interiors, it doesn’t suddenly degrade. Manufacturers like that about it — once it’s installed, you don’t have to keep checking on it.

4. One Material, Many Different Uses Without Much Tweaking

Another useful part about monofilament yarn is how it adapts. Change the polymer, and you get a completely different application.

Shanthi Industries exports several types:

- Nylon

- Polyester

- Polypropylene

- PPS

- Bicomponent monofilament

- PBT

Nylon is for fishing nets and technical textiles, polyester works well for zipper teeth and filters, polypropylene is common in ropes and shade nets, PPS handles high-temperature filtration, and bicomponent yarns go into advanced fabrics.

It slips into different industries without needing big adjustments.

PBT, Nylon, Polypropylene, and Polyester are commonly used for different brush and bristle applications.

5. International Buyers Appreciate the Consistency

A lot of global customers prefer monofilament yarn because it doesn’t shift much in quality. The extrusion process keeps things uniform.

This makes it easier for Shanthi Industries to ship orders that meet expectations every time. Clients get predictable colour, strength, and performance — which reduces production problems on their side.

Final Thoughts

Monofilament yarn isn’t flashy, but it does exactly what it needs to do. It’s strong, steady, and works across so many industries without creating complications. Whether it becomes part of a filter, a zipper, a net, or a brush, it fits right in.

With demand increasing across Europe, the U.S., and parts of Asia, exporters like Shanthi Industries continue supplying grades that manufacturers can rely on — without overthinking the process.

If you’re trying to figure out which type of monofilament yarn fits your product, you can always reach out to Shanthi Industries. They’ll help you sort through the options and get the right match.

Contact us: +91 99022 98755

Email id: info@shanthiindustries.com

Website: https://shanthiindustries.com/