Introduction

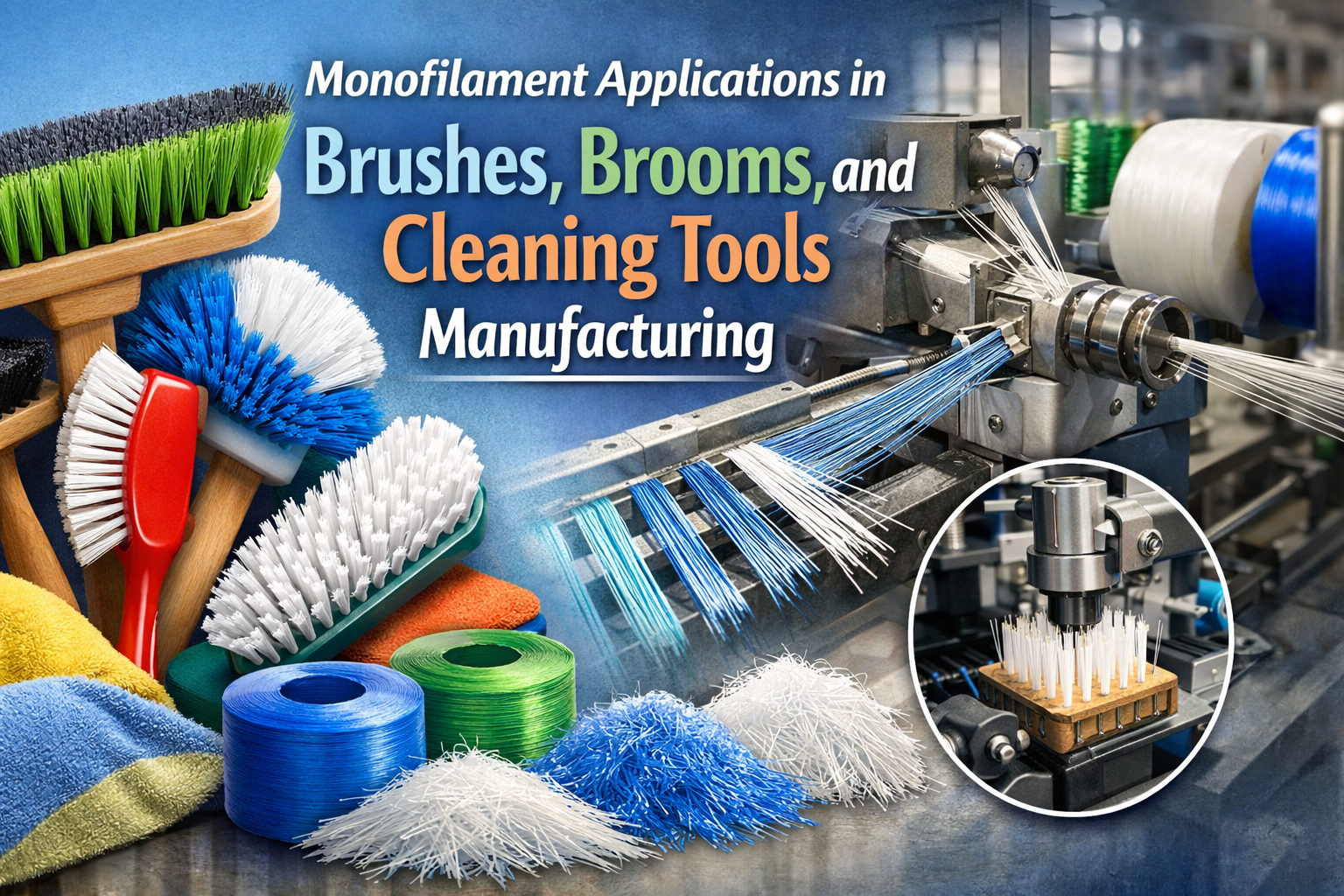

In the manufacturing of brushes, brooms, and cleaning tools, material selection directly impacts performance, durability, and customer satisfaction. One material that has become essential in this industry is monofilament.

Thanks to its strength, flexibility, abrasion resistance, and consistent structure, monofilament is widely used in household, commercial, and industrial cleaning products. From floor brooms and scrub brushes to industrial sweeping tools, monofilament delivers reliable performance across demanding environments.

In this guide, we explore monofilament applications in brushes, brooms, and cleaning tools manufacturing, why manufacturers prefer it, and how it improves product quality.

Read about the core benefits of monofilament yarn in our guide 5 Benefits of Using Monofilament Yarn in Your Products

What Is Monofilament?

Monofilament means a single continuous synthetic filament made from polymers such as polyester, nylon, or polypropylene. Unlike multifilament fibers, monofilament has a uniform diameter and smooth surface, which makes it ideal for repetitive mechanical use.

In cleaning tools, this structure allows monofilament bristles to retain shape, resist wear, and maintain cleaning efficiency over time.

To understand the versatility of monofilament in various products, see our article Polyester Monofilament Yarn: The Material That Holds Its Ground

Why Monofilament Is Ideal for Brushes and Brooms

The cleaning tools industry requires materials that can withstand constant friction, moisture exposure, and surface contact.

Key Reasons Manufacturers Choose Monofilament

- High abrasion resistance

- Excellent flex recovery

- Consistent stiffness levels

- Resistance to moisture and chemicals

- Long service life

- Easy maintenance and hygiene

These characteristics make monofilament the preferred choice for bristles and filaments in cleaning products.

Monofilament Applications in Brush Manufacturing

1. Household Cleaning Brushes

Monofilament is widely used in:

- Scrub brushes

- Toilet brushes

- Dishwashing brushes

- Utility cleaning brushes

Its stiffness can be customized to ensure effective dirt removal without damaging surfaces.

2. Industrial and Commercial Brushes

In industrial environments, brushes face heavy wear. Monofilament is used in:

- Floor scrubber brushes

- Conveyor cleaning brushes

- Equipment cleaning tools

Its durability ensures consistent cleaning performance even under continuous use.

3. Specialty Brushes

Monofilament is also used in:

- Bottle cleaning brushes

- Automotive detailing brushes

- Precision cleaning tools

The uniform filament structure allows precise cleaning in tight or delicate areas.

Monofilament Applications in Broom Manufacturing

1. Household Brooms

Monofilament bristles are commonly used in:

- Indoor floor brooms

- Outdoor sweeping brooms

They provide the right balance between flexibility and stiffness, making sweeping more efficient.

2. Industrial Sweeping Brooms

For factories, warehouses, and construction sites, monofilament brooms offer:

- High wear resistance

- Excellent debris pickup

- Long operational life

These features reduce replacement frequency and maintenance costs.

3. Heavy-Duty Outdoor Brooms

Monofilament performs well in:

- Road sweeping brooms

- Yard and garden brooms

It withstands rough surfaces and harsh weather conditions.

Monofilament in Modern Cleaning Tools

Beyond traditional brushes and brooms, monofilament is used in advanced cleaning tools such as:

- Rotary cleaning heads

- Mechanical sweepers

- Automated cleaning systems

Its uniformity ensures balanced rotation and consistent cleaning results.

Key Properties of Monofilament for Cleaning Tools

Performance Properties

- Abrasion Resistance: Withstands repeated surface contact

- Flexibility with Memory: Returns to original shape after bending

- Chemical Resistance: Performs well with detergents and cleaning agents

- Moisture Resistance: Does not absorb water easily

Design Advantages

- Available in multiple diameters

- Customizable stiffness levels

- Color customization for branding

- Smooth surface for hygiene

When compared to natural fibers or multifilament materials, monofilament offers clear advantages. For modern cleaning tools, monofilament is the most reliable and cost-effective option.

How Manufacturers Choose the Right Monofilament

Selecting the right monofilament depends on application needs.

Key Selection Factors

- Polymer type (polypropylene, nylon, polyester)

- Filament diameter

- Stiffness and flexibility requirements

- Chemical exposure

- End-user environment

Working with an experienced monofilament manufacturer ensures optimal performance and product consistency.

Sustainability in Cleaning Tool Manufacturing

Monofilament supports sustainability goals by:

- Offering longer product lifespan

- Reducing replacement frequency

- Being recyclable depending on polymer type

- Minimizing fiber shedding

Many manufacturers are shifting toward eco-conscious monofilament solutions.

Frequently Asked Questions (FAQ)

Why is monofilament used in brush and broom manufacturing?

Monofilament is used because it provides durability, flexibility, moisture resistance, and consistent cleaning performance.

Which monofilament material is best for cleaning tools?

Polypropylene, polyester and nylon monofilaments are commonly used due to their strength and chemical resistance.

Is monofilament better than natural bristles?

Yes. Monofilament lasts longer, resists moisture, and maintains shape better than natural fibers.

Can monofilament stiffness be customized?

Yes. Manufacturers can adjust filament diameter and material to achieve the required stiffness.

Conclusion

Monofilament applications in brushes, brooms, and cleaning tools manufacturing play a critical role in delivering durable, high-performance products. Its strength, flexibility, and resistance to wear make it the material of choice for modern cleaning solutions.

For manufacturers aiming to improve product quality, reduce maintenance costs, and enhance user satisfaction, monofilament offers unmatched value.

About Shanthi Industries

Shanthi Industries is a trusted monofilament manufacturer, supplying high-quality, customizable monofilament solutions for brush, broom, and cleaning tool manufacturers.

Contact Shanthi Industries today for custom monofilament solutions.

CTA

If you’re trying to figure out which type of monofilament yarn fits your product, you can always reach out to Shanthi Industries. We’ll help you sort through the options and get the right match.

Contact us: +91 99022 98755