Introduction

In high-performance industrial environments, material selection plays a decisive role in determining efficiency, durability, operational stability, and long-term cost control. Industries such as filtration, automotive, engineering, agriculture, and technical textiles rely on materials that can perform consistently under continuous mechanical stress, temperature variations, moisture exposure, and chemical contact.

This is where monofilament yarn stands out as a trusted industrial solution. Engineered for precision and strength, monofilament delivers predictable performance and extended service life across demanding applications. Rather than focusing on basic definitions already covered in earlier blogs, this article explains why monofilament is ideal for high-performance industrial usage—from real-world durability benefits to cost-efficiency and operational reliability.

What Makes Monofilament Suitable for High-Performance Industrial Usage?

Monofilament is ideal for high-performance industrial usage because it offers uniform strength, excellent durability, dimensional stability, and resistance to harsh operating conditions. These properties ensure reliable performance in continuous, load-bearing, and precision-driven industrial systems.

1. Consistent Performance Through Engineered Uniformity

Industrial systems depend on materials that behave consistently over time. Variations in thickness, strength, or structure can lead to system inefficiencies or failure.

Monofilament is engineered with:

- Uniform diameter along its entire length

- Predictable mechanical behavior

- Stable structural integrity under load

This consistency is critical in industrial filtration, engineered mesh, and reinforcement applications, where performance accuracy cannot fluctuate.

2. High Tensile Strength for Load-Bearing Applications

High-performance industrial usage often involves continuous tension, pressure, and repetitive motion. Monofilament provides high tensile strength that supports:

- Load-bearing structures

- Reinforcement layers

- Industrial meshes and screens

Certain variants, such as nylon monofilament, are particularly valued for their strength and resilience. You can explore its capabilities in detail in the blog

Nylon Monofilament: High-Performance Filament for Diverse Applications, which highlights how nylon-based monofilaments perform across demanding industrial environments.

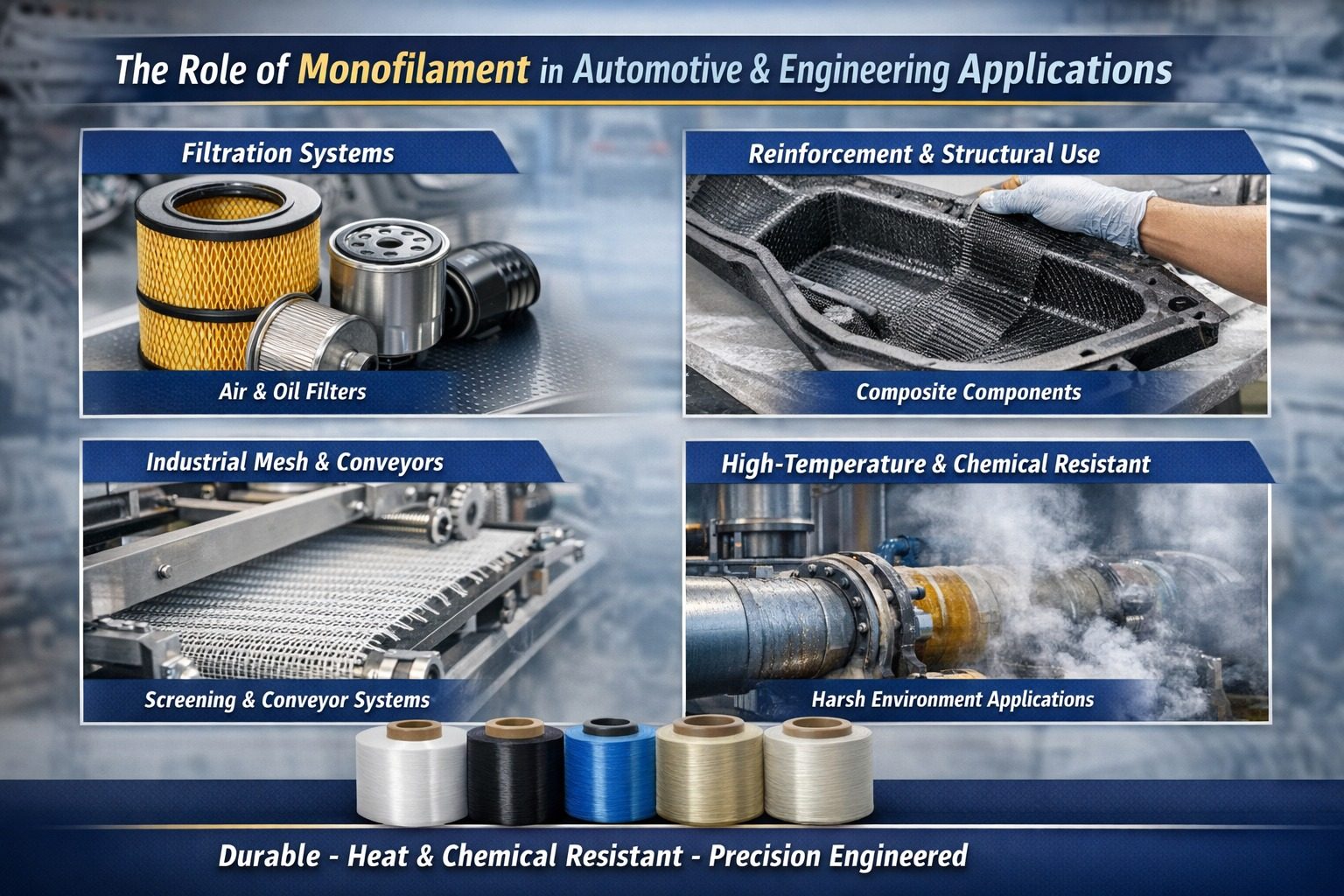

3. Exceptional Durability in Harsh Industrial Environments

Industrial environments expose materials to:

- Heat and temperature variation

- Moisture and humidity

- Oils, solvents, and chemicals

Monofilament maintains performance because it:

- Absorbs minimal moisture

- Resists chemical degradation

- Retains strength under prolonged exposure

For industries requiring long service life and reliability, monofilament significantly reduces premature material failure.

4. Abrasion Resistance for Continuous Operations

In industrial usage, materials often experience constant friction and surface contact. Over time, abrasion can weaken materials and disrupt production.

Monofilament’s smooth surface structure provides:

- High abrasion resistance

- Reduced surface wear

- Minimal material breakdown

This makes it ideal for continuous-operation systems where downtime must be minimized.

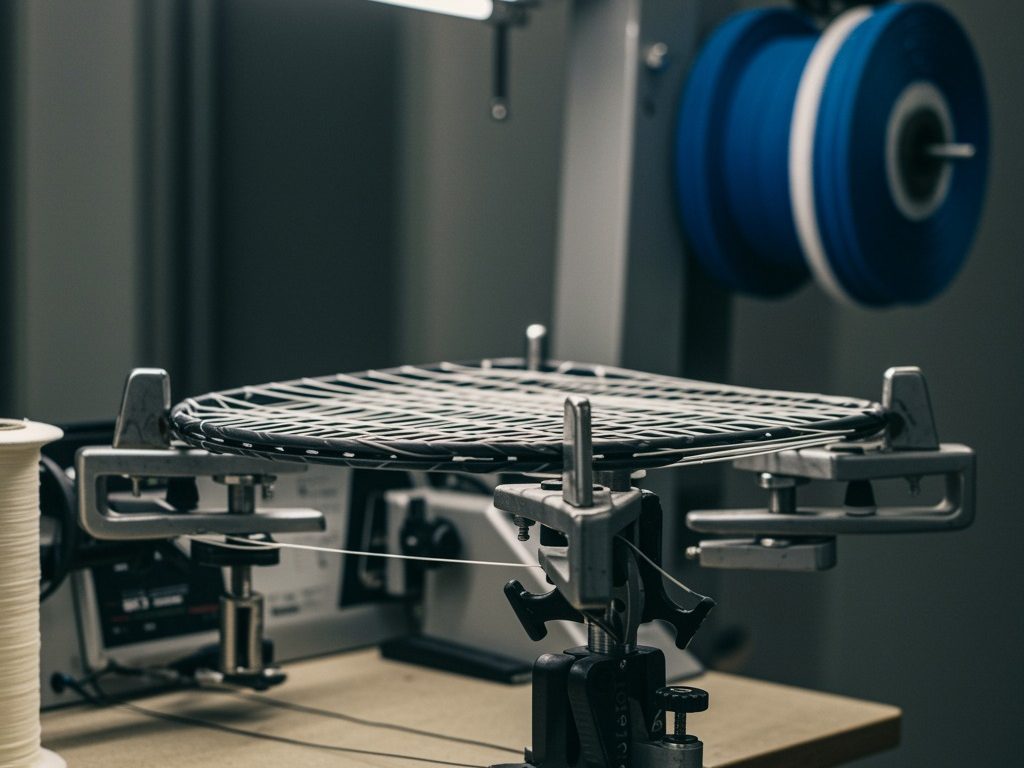

5. Dimensional Stability Under Mechanical and Thermal Stress

High-performance industrial applications demand materials that retain their shape and functional properties under pressure and heat.

Monofilament delivers excellent dimensional stability by:

- Maintaining consistent pore size in mesh applications

- Preventing sagging or distortion under load

- Withstanding thermal expansion within controlled limits

This stability is essential in precision filtration, airflow systems, and engineered textile structures.

6. Optimized Performance in Filtration and Separation Systems

Filtration efficiency depends heavily on uniform pore size and consistent flow behavior. Monofilament is widely used in industrial filtration because it provides:

- Accurate and repeatable filtration performance

- Improved airflow or fluid flow

- Resistance to clogging and contamination buildup

Its smooth surface also allows easier cleaning, extending the operational life of filtration systems.

7. Versatility Across Multiple Industrial Sectors

One reason monofilament is ideal for high-performance industrial usage is its adaptability across industries. It is commonly used in:

- Industrial filtration and screening

- Automotive and engineering components

- Agricultural nets and protective systems

- Technical and functional textiles

- Environmental and separation systems

- Oral care and hygiene applications

By adjusting polymer type, diameter, and stiffness, monofilament can be customized to meet specific industrial performance requirements.

8. Reduced Maintenance and Operational Costs

From an industrial standpoint, performance must be balanced with cost efficiency. Monofilament contributes to lower total cost of ownership by:

- Extending replacement cycles

- Reducing maintenance frequency

- Minimizing unplanned downtime

- Maintaining performance consistency

Over time, these benefits translate into measurable operational savings, especially in large-scale industrial systems.

9. Long-Term Sustainability Through Material Longevity

Sustainability in industrial manufacturing is increasingly driven by durable, long-lasting materials. Monofilament supports sustainability goals by:

- Reducing material waste through longer service life

- Minimizing fiber shedding

- Supporting recyclable polymer options

Using monofilament aligns performance-driven manufacturing with responsible material usage.

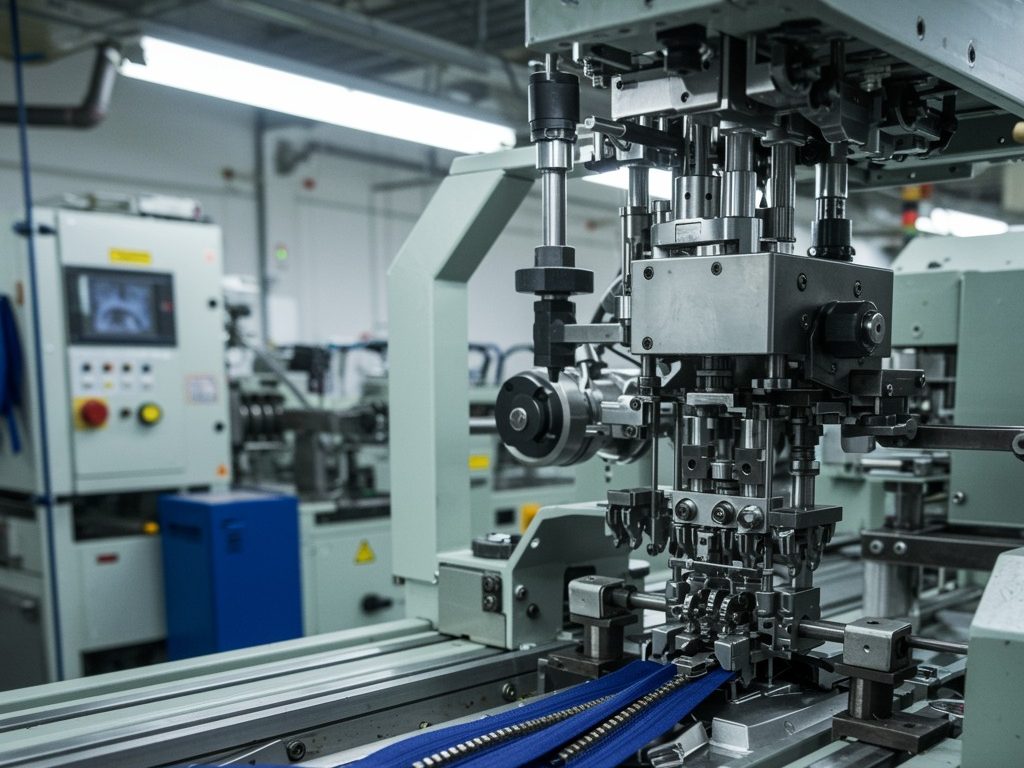

How to Choose the Right Monofilament for High-Performance Industrial Usage

Selecting the right monofilament depends on several factors:

- Polymer type (polyester, nylon, polypropylene, PPS)

- Filament diameter and stiffness

- Exposure to heat, chemicals, or moisture

- Mechanical load and operational duration

- End-use industrial environment

Working with an experienced manufacturer ensures the monofilament is engineered precisely for your application, maximizing performance and reliability.

Conclusion

Monofilament has proven itself as an essential material for high-performance industrial usage due to its engineered consistency, mechanical strength, durability, and adaptability. Across filtration, engineering, automotive, and technical textile applications, it delivers reliable performance where failure is not an option.

For industries focused on efficiency, longevity, and precision, monofilament remains a material of choice that supports both operational excellence and long-term value.

About Shanthi Industries

With extensive experience in monofilament manufacturing, Shanthi Industries delivers high-quality, customized monofilament solutions tailored to industrial requirements. Our expertise ensures consistent performance, reliability, and customer satisfaction.

Looking for custom monofilament fabric solutions? Contact Shanthi Industries today.

If you’re trying to figure out which type of monofilament yarn fits your product, you can always reach out to Shanthi Industries. We’ll help you sort through the options and get the right match.

Contact us: +91 99022 98755

Email id: info@shanthiindustries.com

Website: https://shanthiindustries.com/

Frequently Asked Questions (FAQ)

Why is monofilament preferred for high-performance industrial usage?

Monofilament is preferred because it provides consistent strength, durability, abrasion resistance, and dimensional stability in demanding industrial environments.

Can monofilament withstand continuous industrial operation?

Yes. Monofilament is engineered for long operational cycles with minimal degradation, making it suitable for continuous-use systems.

Is monofilament resistant to chemicals and heat?

Depending on the polymer used, monofilament can resist chemicals, moisture, and elevated temperatures common in industrial settings.

Does monofilament reduce industrial maintenance costs?

Yes. Its durability and wear resistance reduce replacement frequency and downtime, lowering overall maintenance costs.