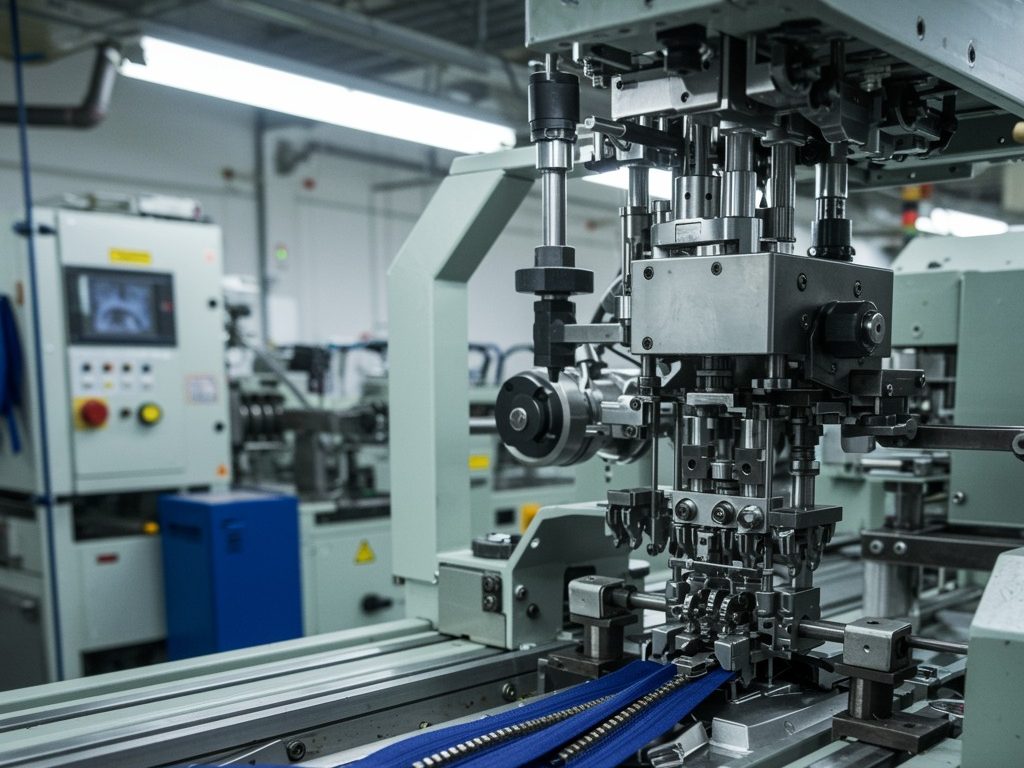

We don’t think much about zippers. We just expect them to work. A smooth pull, a clean lock, no snagging — that’s what feels “normal.”

But when a zipper catches or separates, even once, we notice it immediately.

The part of the zipper responsible for that smooth experience isn’t the slider or the tape.

It’s the teeth — and more specifically, the material the teeth are made from.

For many zipper manufacturers, that material is polyester monofilament.

Not loud, not flashy, just reliable. The kind of reliability that matters only when it’s missing.

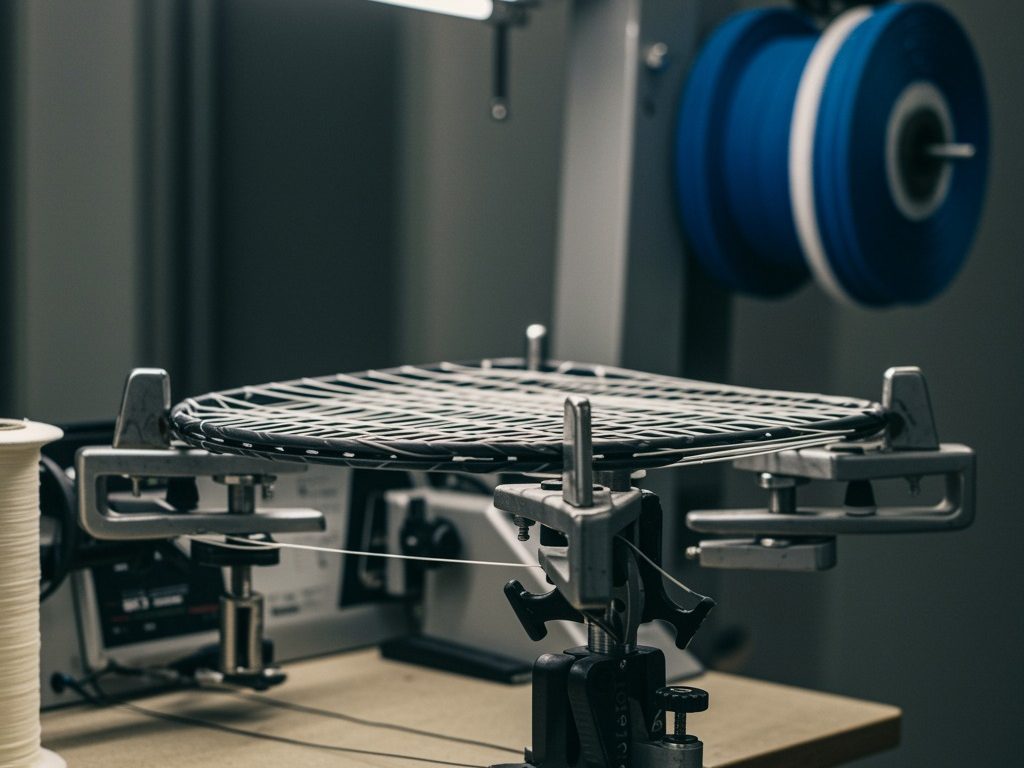

What Makes Polyester Monofilament Suited for Zipper Teeth

Zippers go through small, repetitive stress — thousands of openings, closes, pulls, bends. The teeth need to stay aligned, hold shape, and move cleanly. Polyester monofilament works because it has a kind of steady temperament:

- It keeps its form rather than stretching out or going soft

- It doesn’t absorb moisture, so it won’t swell or warp

- It handles friction calmly — gradual wear instead of sudden failure

- It stays stable in heat, cold, and constant movement

And because the strand is single and continuous, not twisted like multifilament yarn, its behaviour is predictable — which is exactly what zipper teeth need.

A zipper that glides easily isn’t lucky.

It’s using the right monofilament.

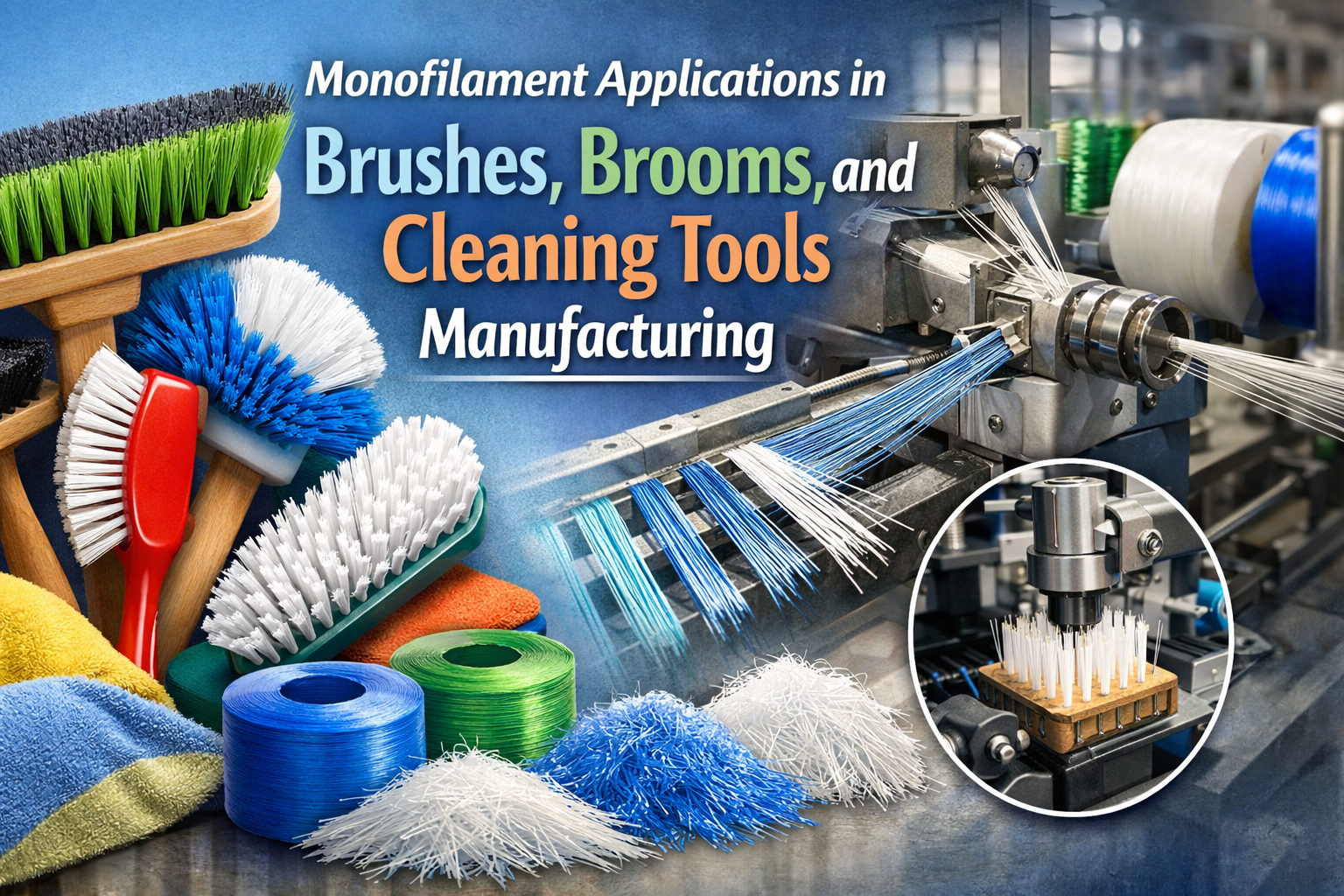

Where This Material Shows Up in Real Life

This kind of filament appears where the zipper is expected to handle real use — not just look decorative.

- Travel bags zipped open and shut in airport lines

- Jackets that bend and flex while someone is moving

- Outdoor and hiking gear exposed to sun, sweat, dust, rain

- Footwear where the angle of tension changes constantly

- Workwear and protective clothing, where failure is unacceptable

- Tents, tarps, storage covers that face weather and stress

You may never look at these products and think about zipper teeth.

But the manufacturers do — because the zipper is the one part that must always work.

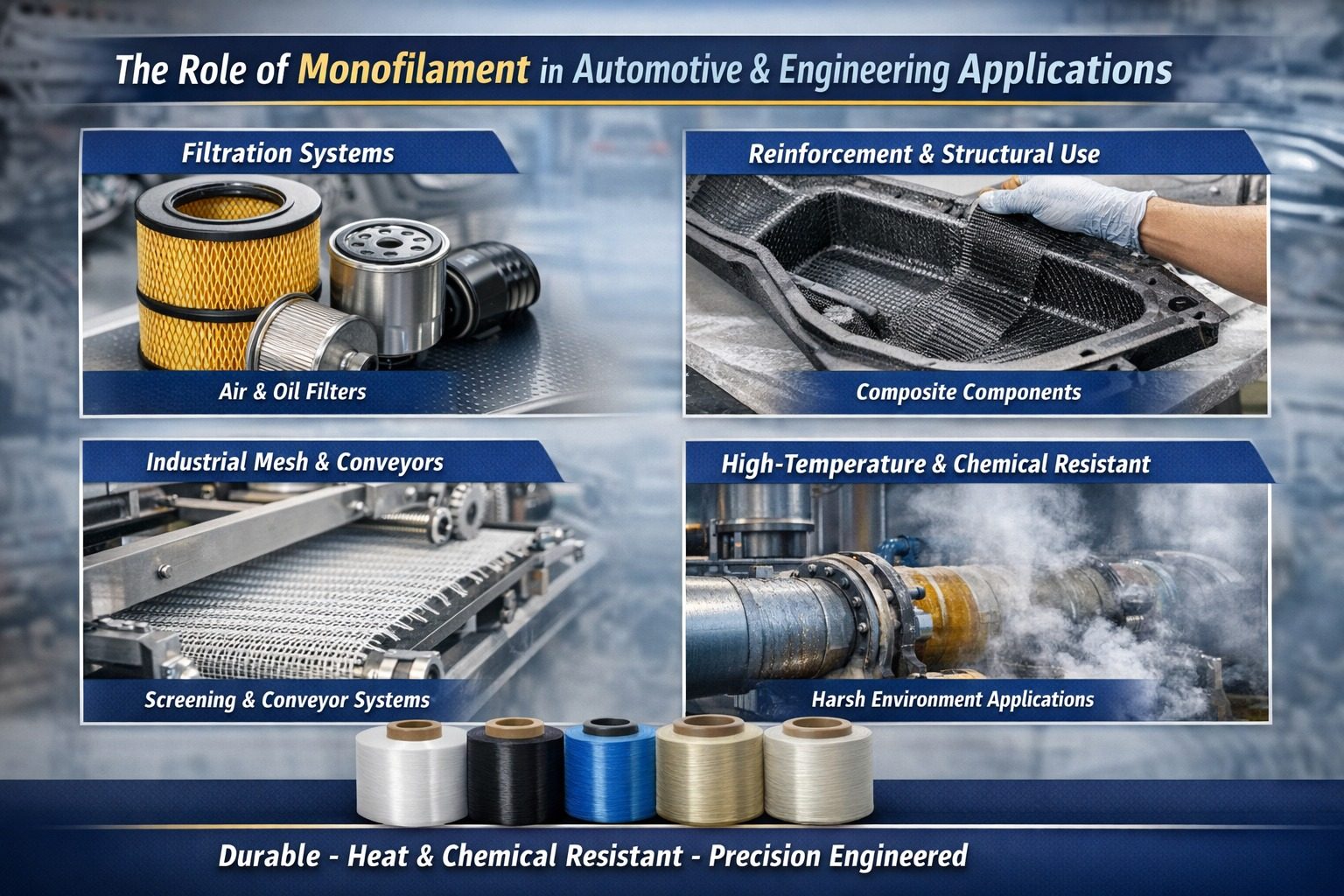

How Shanthi Industries Fits into This Picture

Shanthi Industries works as an export partner for polyester monofilament, selecting filament grades with purpose. The focus is always on matching the material to the zipper’s real-world use, not just supplying volume.

A zipper on a winter jacket and a zipper on a heavy-duty travel case look similar, but they don’t feel the same.

They’re not supposed to.

So, the process starts with understanding:

- How the zipper will be used

- How much stress it will handle

- How often it will be opened and closed

- What kind of environment it will live in

Only then is the monofilament selected.

Shanthi Industries exports zipper and accessory manufacturers in the United States, Germany, Italy, Turkey, Vietnam, Thailand, South Korea, and Brazil — where zipper reliability isn’t just a detail, it’s a requirement.

What the Right Monofilament Changes in a Product

When the filament grade matches the function, small things become noticeably better:

- The zipper moves without hesitation

- The slider doesn’t skip teeth

- The teeth stay aligned longer

- The product feels like it was made intentionally, not cheaply

- The customer never has a “zipper problem” moment

And that’s the interesting part —

good material work is often invisible.

The zipper simply works.

The user doesn’t think twice.

And the product earns quiet trust.

Conclusion

A zipper is a tiny mechanism, but it affects how a product feels every single time it’s used. Polyester monofilament for zipper teeth is one of those behind-the-scenes choices that determines whether something feels cheap and short-lived — or sturdy, smooth, and made with care.

Selecting the right filament isn’t just a technical decision. It’s a commitment to durability, reliability, and user experience.

The best products don’t ask for attention. They work — consistently.

For Export Enquiries

Shanthi Industries

Contant: +91 99022 98755

Email: info@shanthiindustries.com

Website: https://shanthiindustries.com/