Introduction

The automotive and engineering sectors operate in environments that demand precision, durability, and consistent material performance. Components are exposed to mechanical stress, vibration, heat, moisture, and chemicals—making material selection a critical factor in product reliability and safety.

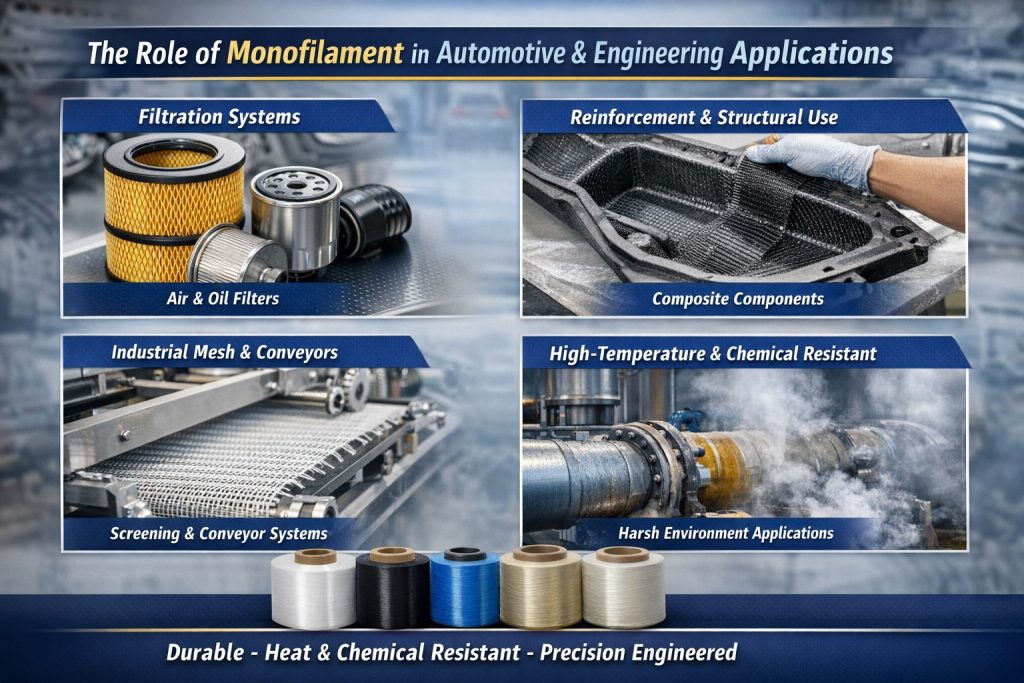

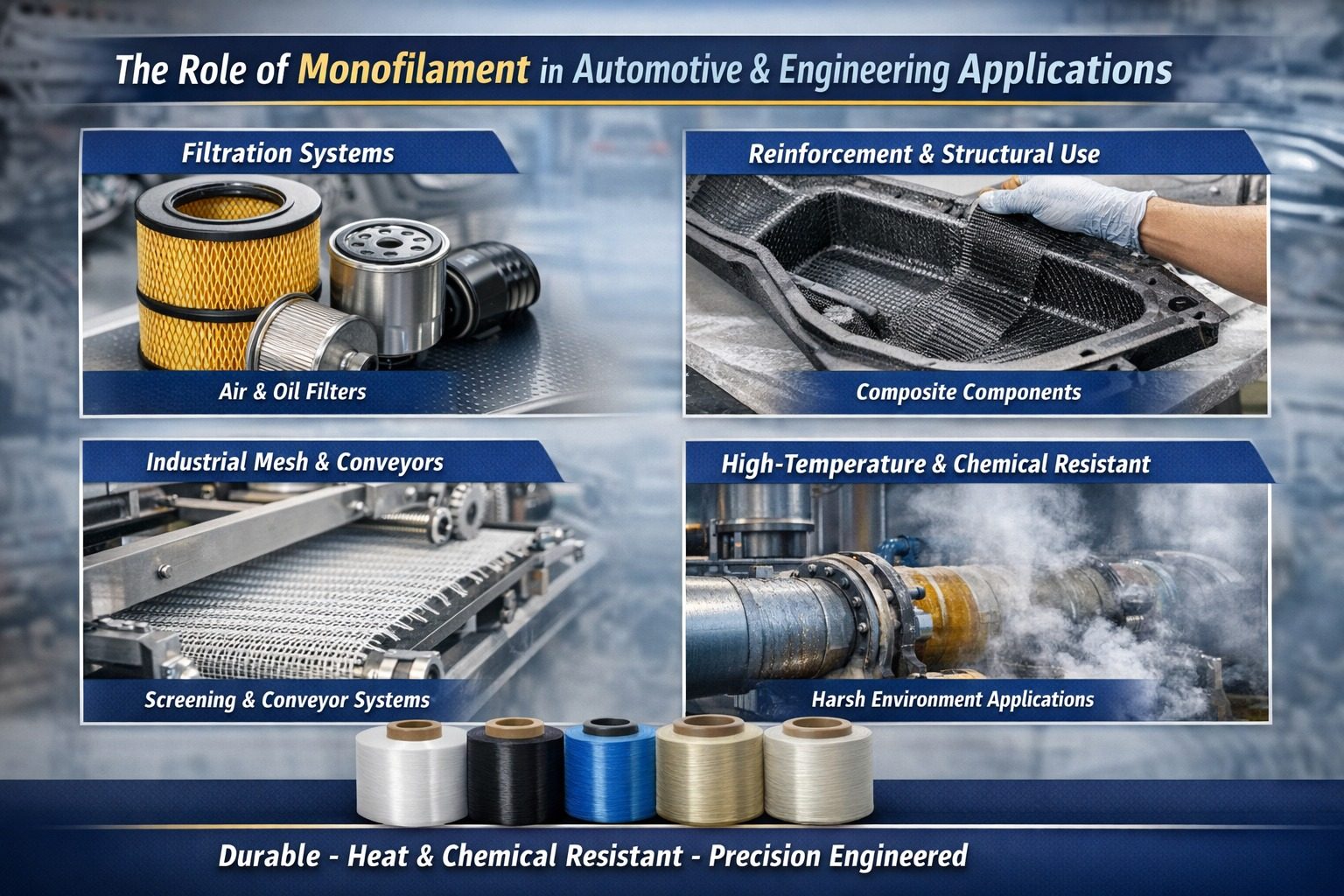

Monofilament plays a vital role in meeting these demands. Its uniform structure, dimensional stability, and engineered performance make it an essential material across a wide range of automotive and engineering applications. From filtration and airflow systems to reinforcement structures and technical meshes, monofilament contributes directly to efficiency, longevity, and performance.

This blog explores the role of monofilament in automotive and engineering applications, focusing on where and why it is used.

Why Automotive and Engineering Industries Rely on Monofilament

Automotive and engineering components must maintain performance under continuous operational stress. Monofilament is preferred because it delivers:

- High tensile strength

- Excellent dimensional stability

- Resistance to abrasion and fatigue

- Moisture, oil, and chemical resistance

- Long service life with minimal degradation

These properties help manufacturers reduce failures, improve consistency, and meet strict industry standards.

Role of Monofilament in Automotive Applications

1. Filtration Systems

Monofilament is extensively used in automotive:

- Air filtration systems

- Fuel filters

- Oil filtration components

Its consistent filament diameter enables uniform pore size, ensuring efficient filtration, reduced clogging, and improved engine protection.

2. Ventilation and Airflow Components

In automotive HVAC and ventilation systems, monofilament is used for:

- Airflow meshes

- Protective screens

- Ventilation covers

The material maintains structural integrity under continuous airflow, vibration, and temperature variation.

3. Reinforcement and Structural Applications

Monofilament serves as a reinforcement element in:

- Composite structures

- Technical fabrics

- Molded automotive components

Its strength and stability improve load distribution, shape retention, and component durability.

4. Interior and Safety Components

In automotive interiors, monofilament is used in:

- Seat reinforcement layers

- Spacer structures

- Protective linings and support components

These applications benefit from monofilament’s precision and fatigue resistance, helping meet safety and comfort requirements.

Role of Monofilament in Engineering Applications

1. Industrial Mesh and Screening

Engineering applications often require high-precision mesh structures for:

- Separation and screening systems

- Protective barriers

- Ventilation and airflow control

Monofilament provides uniform openings, high strength, and long-term dimensional stability.

2. Conveyor and Mechanical Systems

Monofilament is used in engineering systems such as:

- Conveyor belts

- Mechanical guides

- Screening and sorting equipment

Its abrasion resistance ensures smooth operation and reduced maintenance downtime.

You can learn more about material resilience in diverse settings from the PPS Monofilament Yarn: Created for the Toughest Working Environments.

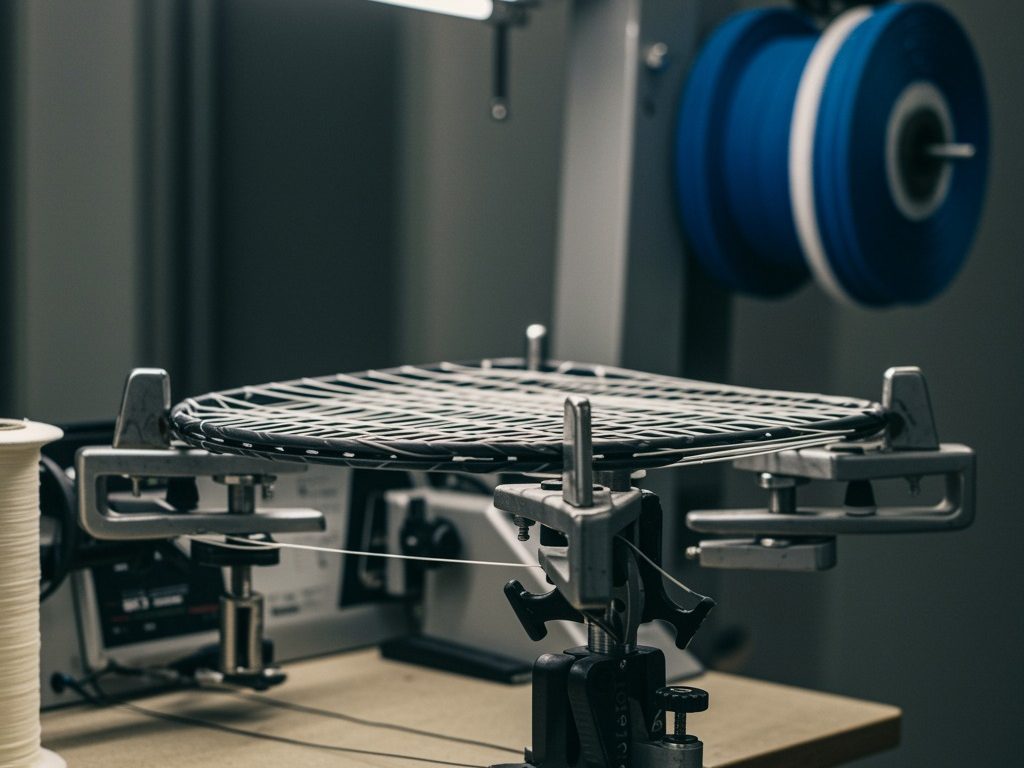

3. Technical and Functional Textiles

Engineering environments rely on monofilament in:

- Technical textile structures

- Reinforcement layers

- Spacer and structural fabrics

These materials are critical for industrial machinery and engineered assemblies.

4. High-Temperature and Chemical-Resistant Applications

Specialty monofilaments are designed for:

- High-temperature environments

- Chemically aggressive processes

- Continuous industrial operation

Such filaments are widely used in advanced engineering systems where standard materials fail.

Key Performance Advantages for Automotive & Engineering Use

Mechanical Performance

- High load-bearing capacity

- Resistance to fatigue and deformation

- Stable performance under vibration

Environmental Resistance

- Moisture and humidity resistance

- Oil and chemical resistance

- Thermal stability (depending on polymer selection)

Manufacturing Advantages

- Consistent filament diameter

- Customizable stiffness and strength

- Compatibility with automated production processes

Monofilament vs Alternative Materials

When compared with other commonly used materials:

| Feature | Monofilament | Multifilament | Natural Fibers |

| Strength Consistency | High | Moderate | Low |

| Durability | Excellent | Moderate | Low |

| Moisture Resistance | Excellent | Moderate | Poor |

| Maintenance | Easy | Moderate | High |

| Industrial Suitability | Ideal | Limited | Limited |

Monofilament offers predictable performance and longer lifecycle, making it the preferred choice for automotive and engineering applications.

Selecting the Right Monofilament for Automotive & Engineering Needs

Choosing the correct monofilament depends on:

- Polymer type (nylon, polyester, PP, PPS)

- Filament diameter and stiffness

- Heat and chemical exposure

- Mechanical load requirements

- Regulatory and safety standards

Working with an experienced monofilament manufacturer ensures application-specific optimization.

Sustainability and Efficiency Benefits

Monofilament contributes to sustainability by:

- Extending component lifespan

- Reducing replacement frequency

- Minimizing fiber shedding

- Supporting recyclable polymer options

Precision manufacturing further reduces material waste and improves efficiency.

For environmentally focused materials, you can also explore PLA Yarn: The Future of Sustainable Textiles.

Frequently Asked Questions (FAQ)

1. Why is monofilament preferred in automotive applications?

Because it offers durability, dimensional stability, and resistance to heat, moisture, and chemicals.

2. Can monofilament withstand engineering-grade stress?

Yes. Monofilament is engineered to handle mechanical stress, vibration, and continuous operation.

3. Is monofilament suitable for high-temperature environments?

Specialty monofilaments can perform reliably in high-temperature and chemically aggressive conditions.

4. Can monofilament be customized for specific automotive uses?

Yes. Filament diameter, stiffness, and material composition can be customized based on application requirements.

Conclusion

The role of monofilament in automotive and engineering applications is critical to achieving durability, efficiency, and consistent performance. Its engineered properties make it indispensable for filtration, reinforcement, airflow management, and technical systems.

For manufacturers focused on reliability, precision, and long-term value, monofilament remains a proven and trusted solution.

About Shanthi Industries

With extensive experience in monofilament manufacturing, Shanthi Industries delivers high-quality, customized monofilament solutions tailored to industrial requirements. Our expertise ensures consistent performance, reliability, and customer satisfaction.

Looking for custom monofilament fabric solutions? Contact Shanthi Industriestoday.

If you’re trying to figure out which type of monofilament yarn fits your product, you can always reach out to Shanthi Industries. we’ll help you sort through the options and get the right match.

Contact us: +91 99022 98755

Email id: info@shanthiindustries.com

Website: https://shanthiindustries.com/